Logistics

Warehousing & Fulfillment

Transportation

Industries

Technology & Innovations

E-commerce

E-commerce Fulfillment Services

Lease & Maintenance

Semi Trucks

Logistics

E-commerce

Lease & Maintenance

Buy Used Trucks

Updated November 8, 2024

The threat of oceanic shipping disruptions, geopolitical uncertainties, and rising freight rates is prompting U.S. brands to expedite their shipment orders to secure inventory for the peak season. A recent article from CNBC highlights a key driver behind this urgency is companies rushing imports into the U.S., anticipating potential new tariffs. This expectation of heightened trade costs is fueling the strongest container shipment volumes at U.S. ports since mid-2022, as businesses aim to mitigate risk by increasing inventory now.

The surge in imports is filling warehouses with inventory from raw materials to clothes, furniture, electronics, exercise equipment, and more in anticipation of the peak shopping season, which began with back-to-school shopping and ends with the year-end holiday rush. According to the Census Bureau, the inventory-to-sales ratio at U.S. brands, which compares warehouse holdings to retail sales, rose to 1.31 in May, the highest level since May 2020.

This creates an inflection point for supply chains. Getting ahead of the shipping disruptions is only part of the equation. Companies must also have a strategy in place for when the goods reach North America. This includes warehouse space, drayage, workforce, and inventory management.

Surging demand for warehouses

In 2021 and 2022, as shipping volumes climbed, there was a surge in demand for warehouses to store all the inventory coming ashore. That demand was driven by the growth of e-commerce and the flood of container imports hitting U.S. ports. Supply chains were stressed as storage space was hard to find and prices were being driven up.

This is fresh in the mind of supply chain executives and managers as they are looking at economic predictions, while having the memory of sharp and unpredictable swings in consumer demand, product shortages and gluts, shipping delays, and volatile freight prices.

It’s no secret that managing inventory during peaks and valleys presents unique challenges due to unpredictable demand, often resulting in either stock shortages or surplus inventory. Now, add in pulling shipment orders forward. This all can be especially problematic as it needs additional storage and ties up valuable resources.

Flexible warehousing options are essential for handling surplus inventory during these high-demand periods. Scalable warehousing allows businesses to adjust storage capacity as needed, accommodating excess stock without committing to long-term storage solutions.

Short-term warehousing, or temporary warehouse services, and on-demand storage solutions offer excellent options for managing seasonal surplus. These services provide short-term storage spaces that can be rented as needed, offering a cost-effective way to manage excess inventory.

For example, businesses can use these services to store surplus holiday merchandise that didn't sell as expected, freeing up regular warehouse space for more immediate needs.

Proper warehousing during peak season helps businesses maintain efficiency, avoid clutter, and effectively manage surplus stock. By leveraging flexible, temporary, and on-demand storage solutions, you can ensure your operations run smoothly, even when demand fluctuates.

Meeting drayage needs

While warehousing poses one challenge to supply chains bringing orders forward, drayage is just as important. Drayage services are the connective tissue between the ports and warehouse.

The drayage industry faces a variety of critical challenges, including capacity constraints, congestion and delays, compliance and regulations, maintenance and repairs, driver shortages, labor disruptions, appointment challenges, asset allocation and utilization, tight timelines, lack of visibility, outdated legacy software, and cost pressures. All these challenges are passed directly to retailers.

Companies can overcome drayage challenges and expedite the delivery of goods to warehouses by implementing several strategic measures. Optimizing capacity utilization through advanced analytics and dynamic routing can ensure maximum use of available transportation resources, reducing delays and inefficiencies. Improving communication is crucial, as well as investing in real-time tracking systems that enhance shipment visibility while fostering better communication between shippers, carriers, and customers to streamline operations.

Optimizing asset allocation and utilization by using asset management tools and sharing strategies allows better use of available equipment. Adapting to tight timelines with advanced planning tools and maintaining a buffer stock of critical items ensures timely deliveries.

Taking advantage of existing infrastructure

Fortunately for companies there is already infrastructure in place that can help with the storage and movement of inventory coming into U.S. ports. Brands can turn to a third-party logistics (3PL) provider like Ryder that has solutions in place. This includes flexible warehousing solutions in dedicated or multiclient facilities that offer both short-term and long-term options.

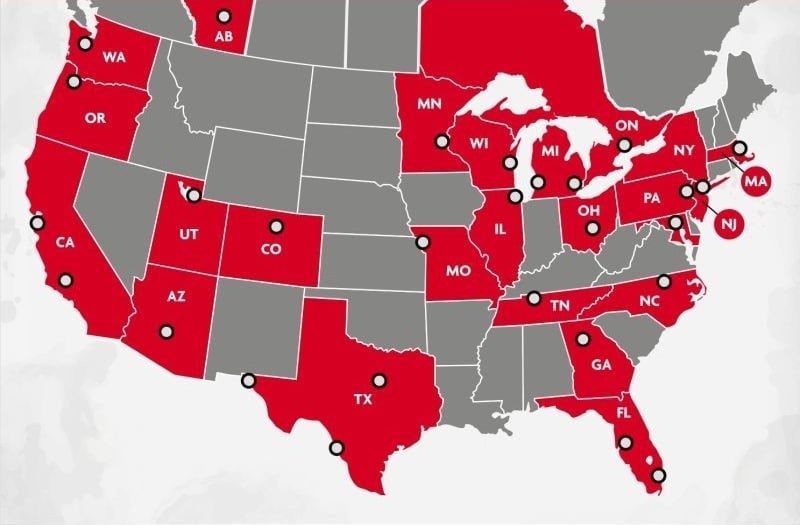

Ryder’s warehouse management network spans North America with strategically located facilities (see below) allowing you to be where your customers are. You also won’t have to invest in technology or a workforce as both are already in place and can be integrated into your current warehouse management system.

Ryder also offers drayage services that include transloading, cross-docking, and full import/export capabilities. This allows you to accelerate inland execution, streamline repetitive tasks, and adapt to changing drayage conditions using our robust data insights and predictive tools.

What’s more? You can benefit from these solutions on their own, or as part of an industry leading port-to-door supply chain solution that is customized to your business and powered by proprietary technology and an experienced workforce.

This is not the first time, or the last time oceanic shipping challenges threaten to disrupt supply chains. However, with the proper strategy, or by trusting a 3PL with the infrastructure, experience, and solutions in place, you will be able to meet your customer’s needs.