Logistics

Warehousing & Fulfillment

Transportation

E-commerce

E-commerce Fulfillment Services

Lease & Maintenance

Semi Trucks

Supply Chain Technology

Logistics

E-commerce

Lease & Maintenance

Buy Used Trucks

The world of supply chain and transportation has seen a number of transformations, driven by technological advancements, regulatory developments, sustainability imperatives, and many other factors along the way.

As the clock ticks down on another year, it’s time to look back at the twists and turns that have defined the supply chain landscape in 2024, and forecast what’s on the horizon for us in 2025.

Overview of Key Shifts in 2024

If working to optimize supply chains and transportation needs has taught us anything, it’s that change is the only constant. In this blog, we’ll explore trends that have come to the forefront this year and how they will impact businesses moving forward. We’ll also share some noteworthy tips to stay ahead of the curve. Here are the major points to consider:

The AI Surge: A New Era in Supply Chain Management

Artificial Intelligence and the Internet of Things (IoT) emerged as the dynamic duo that supercharged supply chain management. With companies integrating machine learning and blockchain into their workflows, transparency became the name of the game. Imagine a supply chain where data flows like an endless stream, keeping not just management but also suppliers and communities in the loop with real-time updates on sustainability performance. That time is here.

By 2030, the market for AI in supply chains is expected to reach $41.23 billion, driven by the need for improved efficiency and the ability to manage complex logistics operations. Supply chains equipped with AI have shown to be over 67% more effective than traditional systems in terms of risk reduction and cost optimization. Expect AI-driven forecasting and predictive capabilities to refine accuracy and quality control further. Companies that secure this technological advantage will find themselves not just surviving—but thriving in the intricate web of global supply chains.

The Double-Edged Sword of Automation

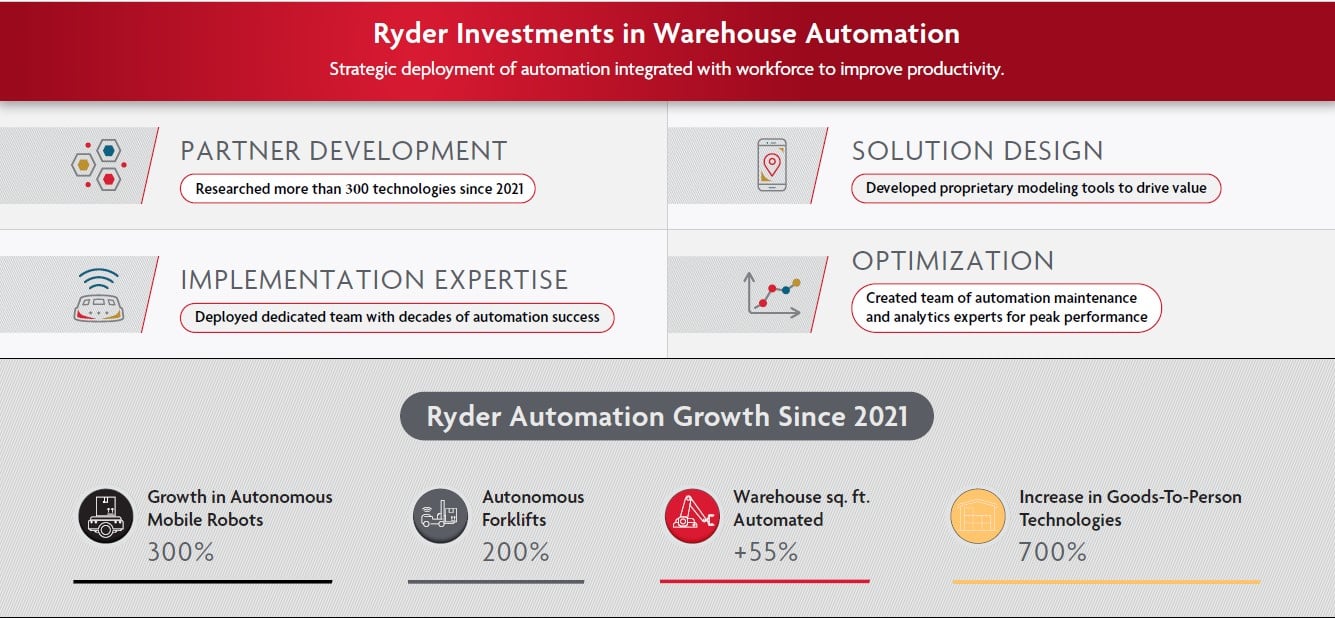

You may hear phrases like digital twins and robotics come up more often in conversation, but what impact will it have on the production and delivery processes, along with shifts in labor demands? Warehouse and logistics automation has reshaped the way businesses operate in today’s landscape, redefining production and delivery processes.

In 2024, we witnessed robots and autonomous vehicles take on roles traditionally held by humans, facilitating efficiency beyond our wildest dreams. However, with efficiency comes responsibility. The potential workforce displacement calls for companies to invest in proactive upskilling initiatives.

Robotics in the Warehouse:

The Role of Digital Twins:

As we jump into 2025, balancing automation with workforce needs will be paramount. A collaborative approach, where human ingenuity and machine efficiency coexist, will lead the way forward.

These shifts are likely to have several implications for procurement leaders:

Nearshoring: A Valuable Solution to Global Disruptions

As global disruptions continue to reshape the business landscape, nearshoring strategies will become increasingly advantageous. Companies are realizing the benefits of sourcing closer to consumer markets—lower lead times, reduced risks, and improved supply chain responsiveness all add up to a winning strategy as we head into 2025.

According to research over the past few years from Deloitte, nearshoring can help companies optimize their supply chains and lower operating costs. The studies found:

Countries benefiting from nearshoring have seen job creation increase significantly, leading to a boost in local economies. For example, the manufacturing sector in Mexico has grown by over 10% as a direct result of increased nearshoring activities.

Beyond the Vote: What a New Administration Means for Supply Chain

Many businesses echoed the same sentiment for months, "Wait and see the results of the election before making any decisions." Well, the time has come and gone. Now that the president has been chosen, it will significantly impact the supply chain, transportation, trucking, and logistics industry.

There is expected to be a rollback on emissions regulations and tariffs raised on imports. These changes may lead to lower operational costs for fleets and an increase in freight volumes while complicating the sector's electrification movement. Some experts predict, with Republicans gaining control in Congress, the transportation landscape may shift dramatically, emphasizing traditional trucking priorities over environmental regulations. To dive deeper into these developments, read what FreightWaves says about how election results will affect the transportation industry.

Data: The New Gold Standard

Data reigns supreme, and you might say it wears a crown of algorithms and insights depending on your BPM (Business Process Management) style.

With over 75% of organizations in 2024 citing the critical role of big data, cloud computing, and AI in navigating supply chain complexities, it’s safe to say that the future belongs to the data-savvy.

Companies can now aggregate data across platforms to craft unified models of their supply chains—a move that has proved pivotal for agility in the face of unpredictable market scenarios.

Fast forward to 2025, and the demand for real-time data access will only intensify. Advanced analytics platforms will push supply chains toward unprecedented levels of agility and responsiveness.

Digital Skills and Workforce Transformation

With the integration of new technologies, the call for professionals with digital skills will resonate louder than ever. Companies must shift gears and invest in workforce training to ensure employees are equipped to harness the power of AI, data analytics, and other digital tools. Those who prioritize upskilling will not only become operational giants; they will outpace competitors left in the dust.

Exploring the New Frontier of Risk Management & Cybersecurity

Geopolitical upheavals keep us on our toes. This year has underscored the importance of robust risk management and cybersecurity strategies as supply chains face vulnerabilities like never before. With a majority of technology executives considering cybersecurity one of the biggest threats to operational stability, organizations are urged to prioritize investment in resilient networks.

Here are some things to note as evidence of why adopting proactive cybersecurity measures are essential:

The integration of AI in security protocols can help safeguard supply chains in real-time, drawing a line in the digital sand against potential threats.

Supply Chains Shaken by Port Strikes

Port strikes that took place significantly impacted shipping and logistics, prompting companies to expedite their freight shipments to mitigate disruptions.

While this approach has helped alleviate some immediate challenges, it has also led to complications regarding warehousing flexibility, as businesses scramble to adapt to the changing supply chain dynamics.

These oceanic shipping disruptions underline the critical balance necessary in logistics management to maintain operations amid labor disputes.

The Road Ahead

Reflecting on 2024 reveals that while the challenges were numerous, the lessons learned are invaluable.

Companies that are agile, data-driven, and willing to invest in their workforce will undoubtedly lead the charge toward a resilient, sustainable future in 2025. Embracing technological advancements while balancing the needs of the workforce will pave the way for a new era of supply chain excellence.

In the dynamic landscape of business, staying ahead means being [prepared] [Ever Better®]. As we step forward, let’s aim to leverage our learnings, nurture innovation, and create supply chains that are not only efficient but also environmentally conscious and aligned with the needs of tomorrow's consumers. The future is knocking—are you ready to open the door?